|

|

|

|

|

The global electronic market: rechargeable batteries, automobiles, LEDs, LCDs,

Full support for touch panels, mobile phones, etc. |

|

|

|

|

|

|

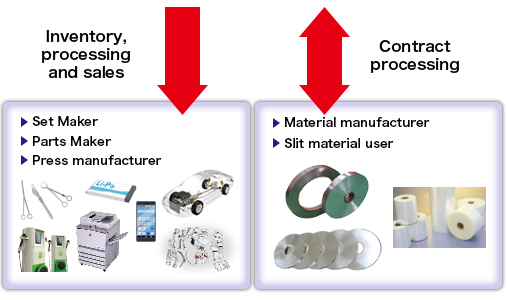

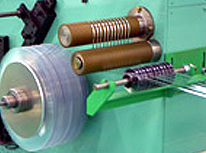

There are three processing lines: precision, ultra-precision, and film slitting, and various metals and film materials are slitted. Surface treatment materials, composite materials, and functional film materials used in electronic parts, automobile parts, and mobile phones, which are increasingly being miniaturized and lightened, are also being slitted. Since its establishment, we are striving to improve slit processing technology.

In particular, our ultra-precision slitting technology has earned highly evaluated not only in Japan but also in other countries around the world. The technology is now attracting attention in various fields around the world. In addition, this technology enables even thinner and finer processing to achieve resource conservation and energy conservation, and supports the production of products that are adapted to environmental problems. We will strive to further improve our technologies. |

|

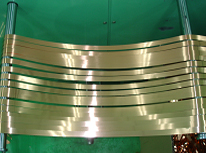

Precision slit line |

| General stainless steel, Precision stainless steel, Stainless steel foils and other metal foils, Nonferrous metals, High-alloy, Silicon steel sheets, Surface treatment materials, etc. |

|

Ultra-precision slit line

(Equipped with semi-clean room, Air shower, and temperature and humidity control.) |

Secondary battery materials, Nonferrous metals, Surface treatment materials, and Cladding materials |

|

Film slit line

(Clean room available, Class 10,000) |

Functional film, Special double-sided tape, Optical film, Acrylic foam, PET separator, Coating film, PP film, etc. |

|

|

|

|

|

Lithium ion secondary batteries, automobiles, LCD backlight units, mobile phones, HDDs, motors, aluminum electrolytic capacitors, semiconductor lead frames, connectors, OA equipment, medical devices, smartphone internals, touch panels, LCDs, printed circuit boards, automotive components, home appliances, electronic packaging materials, etc. |

|

|

| Materials |

Precision stainless steel and various stainless steel materials, non-ferrous metal materials, resin film, metal composite materials, electroplating materials, etc. |

| Size | Precision production line: plate thickness 0.08-2.0mm, width 6.0-500mm

Ultra-precision production line: plate thickness 0.002-1.5mm, width 0.1-350mm

Film production line: plate thickness 0.006-1.0mm, width 4.0mm |

|

|

|

|

|

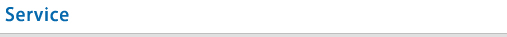

| Giving priority to customer satisfaction, we reserve parent metal with various widths in accordance with customers’ expected requirements and provide slitting services to ship promptly to customers’ specifications. In order to reduce the customers’ inventory pressures and financial burden, we have established a timely supply system for the necessary amount of necessary materials. |

|

|

| |

|

| We have obtained ISO9001 (in 2004) and ISO14001 (in 2006) certification and ISO/TS16949 (in 2016) certification, and conduct high level quality and delivery management as well as in Japan. so as to provide the comprehensive, high-quality and considerate services. |

|

|

| |

|

| We provide processing services with materials supplied by clients. We only charge a processing fee. We process according to the requested specifications and pressure on inventory and capital. |

|

|

| |

|

The settlement currency is possible for both RMB, US dollar and Japanese yen.

It is possible to correspond to both stock sales (advance processing) and consignment processing (charge processing). Payment money can be paid by both US dollars, Japanese yen and RMB. Moreover, the material is stock based on customer's forcasting, and it is slit processing and delivery immediately after the order, and it contributes to the reduction of the customer burden and the burden of the fund. |

|

|

|

|

|

Copyright © Suzhou Iwatani Metal Products Co.,Ltd. All rights reserved.

|

| |

|

|