|

|

|

|

|

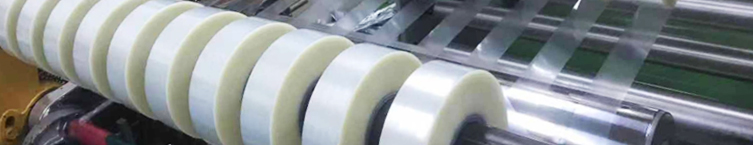

High quality slitting from narrow to wide in a class 10,000 clean room |

|

|

|

|

|

|

We are engaged in slitting various electronic and optical films. We conduct slitting and laminating processes for functional films in a clean room rated as Class 10000. It has a small size, light weight and high performance electronic devices, portable phones, displays, functional films used in semiconductor fields, optical film, special double-sided tape, pet separator, laminated film, acrylic foam, etc.

In addition to the precision slit processing of a wide range of materials in the clean room of the class 10000 level, lamination processing, alcohol cleaning, sheet cutting, sewing machine, etc. are done.

We have also developed products to meet our needs, and supporting technology that's evolving day by day. Its precision processing and product development support product development in terms of resource saving and energy saving, and we will strive to further improve our technologies. |

| |

|

|

|

|

| |

| 4 sets of machine on slitting production line |

Thickness 0.0008~0.1mm、width 0.8~1,600mm

Machine No. 1(1,100mm width) ※Able to clean the front and back sides of film with alcohol.

Machine No. 2(1,450mm width) ※Able to laminate two kinds of material together such as optical film and surface protective film, or tape and release film.

Machine No. 3(1,600mm width) ※Able to process along the sewing line.

Machine No. 4(900mm width) |

| other machine |

Sheet cutting machine |

| Applied materials | Acrylic foam, functional film, special double-sided tape, optical film, PET separator, laminate film, coating film

≫Click here for product details |

| Application |

LCDl、OEL、Touch panel、mobile phones、Semiconductor、auto parts、electronic packaging materials、Lithium-ion batteries |

|

| |

|

We are capable of processing various materials such as PET film, PE/PP films, electrical insulation films, functional films, adhesive tape, buffer material, optical materials, and metal films. Our equipment is able to process the materials with the maximum width of 1600mm. |

| Machining Thickness |

Thickness 0.006mm~1mm |

| Materials Weight |

Max 500kg |

| Material Max. Dia |

φ800mm |

|

|

| |

|

| We slit the materials based on the width specified by clients with the machining accuracy of ±0.1mm. The minimum of slitting width is 0.8mm and clients can request to widen it by 0.1mm. Slitting width below 0.8mm is also available upon requests. |

|

|

| |

|

Countermeasures against unevenness in the core of high-value-added films and measures for clean rooms

Dramatic reduction of film level difference defect due to level difference of winding core.

Contributes to cost reduction and CO2 reduction.

Please consult us for details. |

|

|

| |

|

We provide burn-in test.

Provided to burn-in test within Maximum temperature 80℃ |

|

| |

|

| We are planning to install Corona treatment facility with 1,600mm width. |

|

| |

|

| It’s available to cut at below specifications.

Width : 1,450mm, Length : 60-9999mm, Tolerance : within +/-1.0mm |

|

| |

|

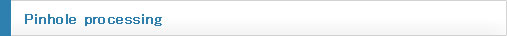

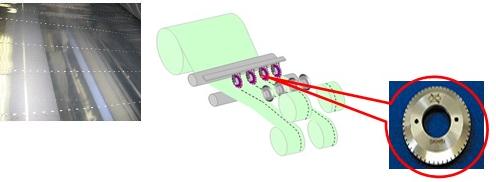

| We provide longitudinal pinhole processing.

The distance and shape is according to client’s request. |

|

|

| |

|

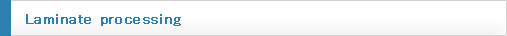

We offer laminate processing such as laminating a surface protection film on an optical film while slitting and laminating a release film on a tape. The lamination for two or three kinds of materials is available upon clients' requests.

【Example】

Diffuser sheet+PET carrier tape

Reflection film+Surface protection film

Special optical film+double-sided(front and back sides)protective film |

|

|

| |

|

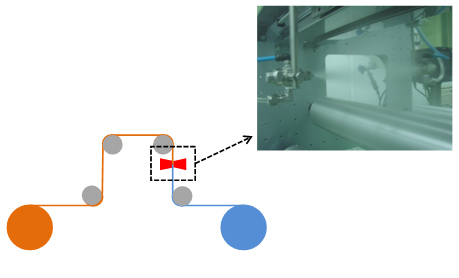

| For industries with a high degree of clean requirements, we available to supply alcohol cleaning process. Our cleaning line offers full cleaning service for the front and back sides of film. Other kinds of cleaning apart from alcohol are also available upon request. |

|

|

| |

|

| Minimum wide between 0.8mm to 10.0mm of micro precise slit processing can be provided. |

|

|

|

|

|

Copyright © Suzhou Iwatani Metal Products Co.,Ltd. All rights reserved.

|

| |

|

|